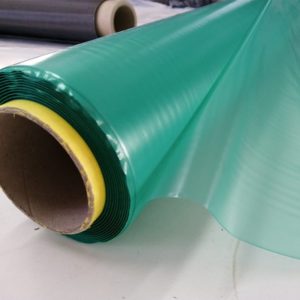

Silicone vacuum bag

Reusable Silicone Bags for the Resin Infusion Process

If you need higher volume production, reusable silicone vacuum bags for the resin infusion production process are the way to go!

With the use of our advanced infusion technology and the new TopGear Silicone machine, reusable silicone vacuum bag membranes can be made in a single day.

If you want higher production volumes out of one mold, save precious time and build a silicone bag for a far quicker turnaround time.

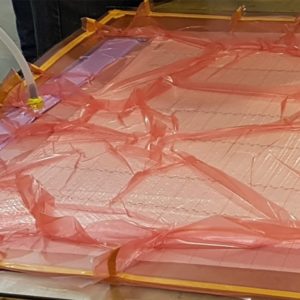

If you are already building your composite parts with resin infusion, there are no face mold changes required to get going with the silicone bag process.

Not only is the silicone bag reusable but the brand-new resin distribution system (Mini Morphs) from Alan Harper Composite in the UK allows you to control when you want the resin to flow and where you need it to be. Amazingly the mini morph will disappear without leaving a trace on your product as soon as it is no longer needed.

Durability: Silicone bags are more resistant to wear and tear and can be reused multiple times. Lifting eyes can be installed into the silicone bags for ease of removal as well as reduced storage space (in the air)

Consistency: Silicone bags maintain their shape and seal far quicker, even over multiple uses, resulting in more predictable process control and consistent results

Cost-effective: Reusable silicone bags recover their cost very quickly by increasing the output of the parts being produced.

Some production lines are getting between 200 & 400 parts from a single bag.

Polyester and Vinyl ester production lines all over the world are Going Green and taking advantage of the silicone bag infusion technology.

Come join our technical team at Aerontec to see how the technology could change your view of the composite production capability.

View Silicone infusion bag case study