Multi Cut Contour Core (MC3)

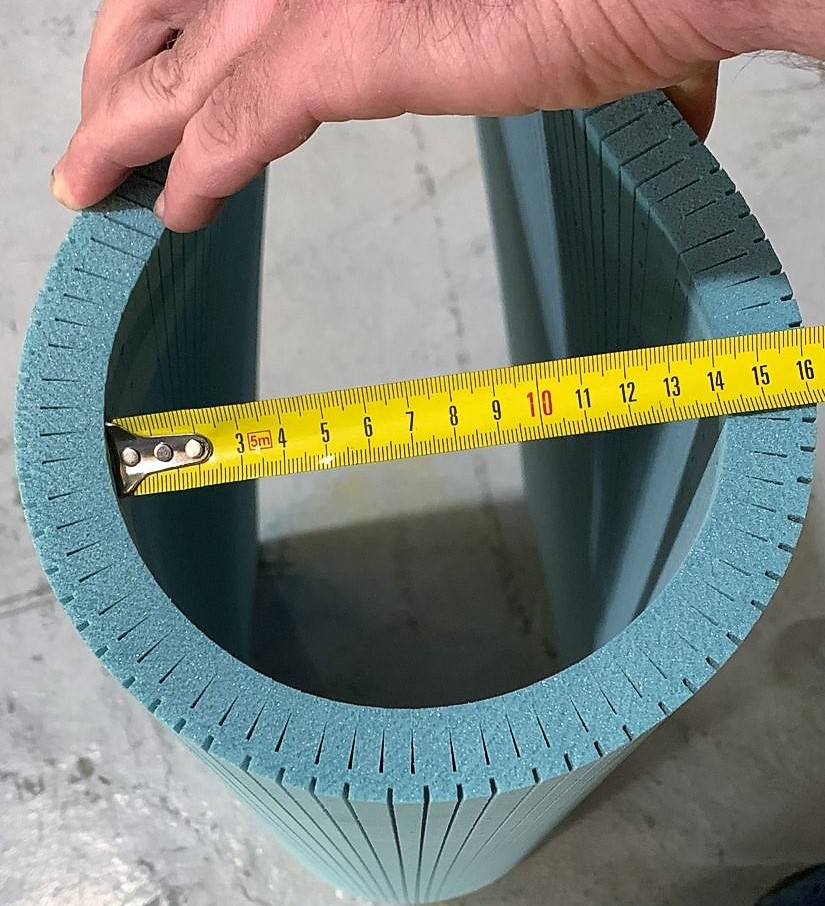

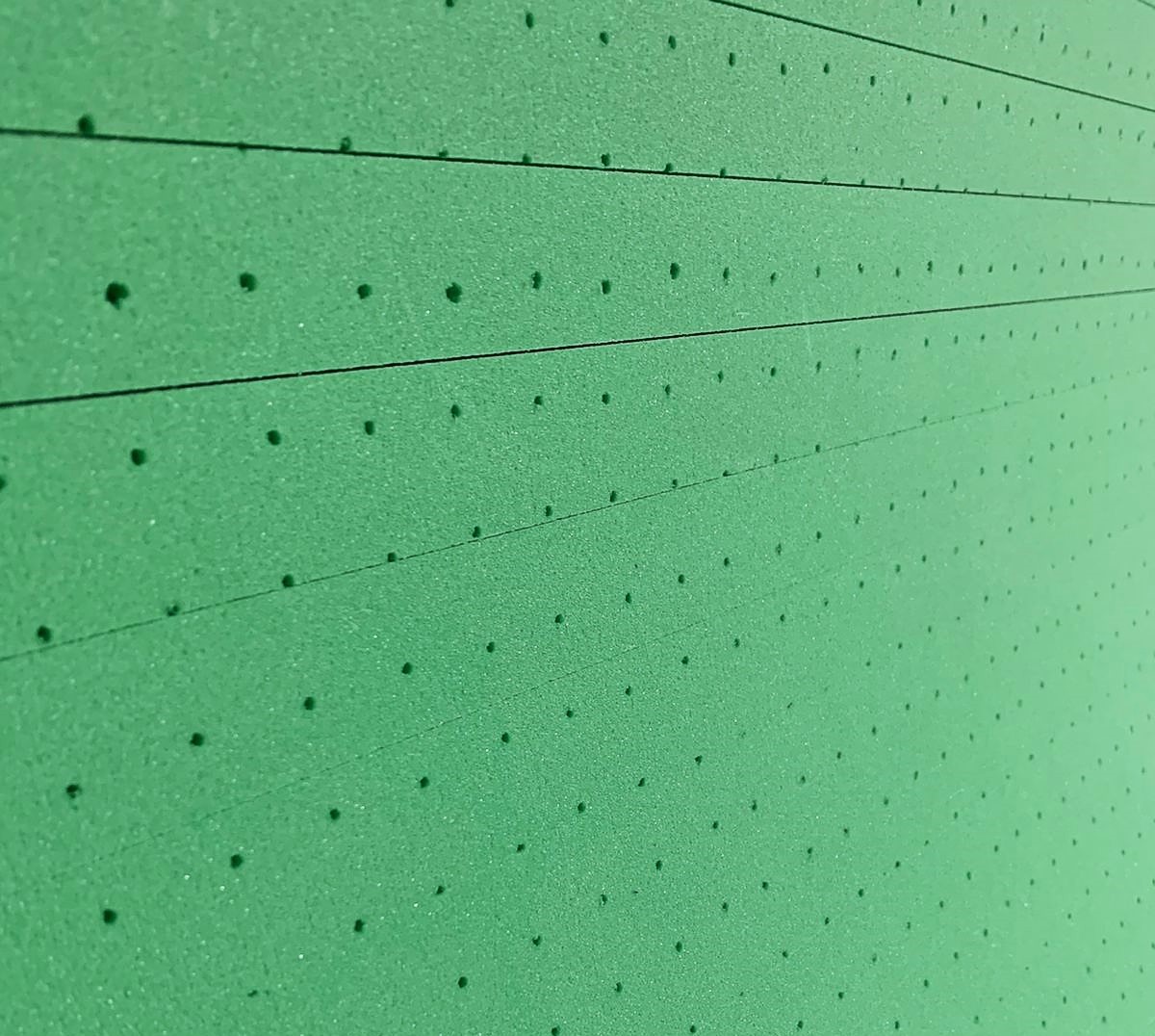

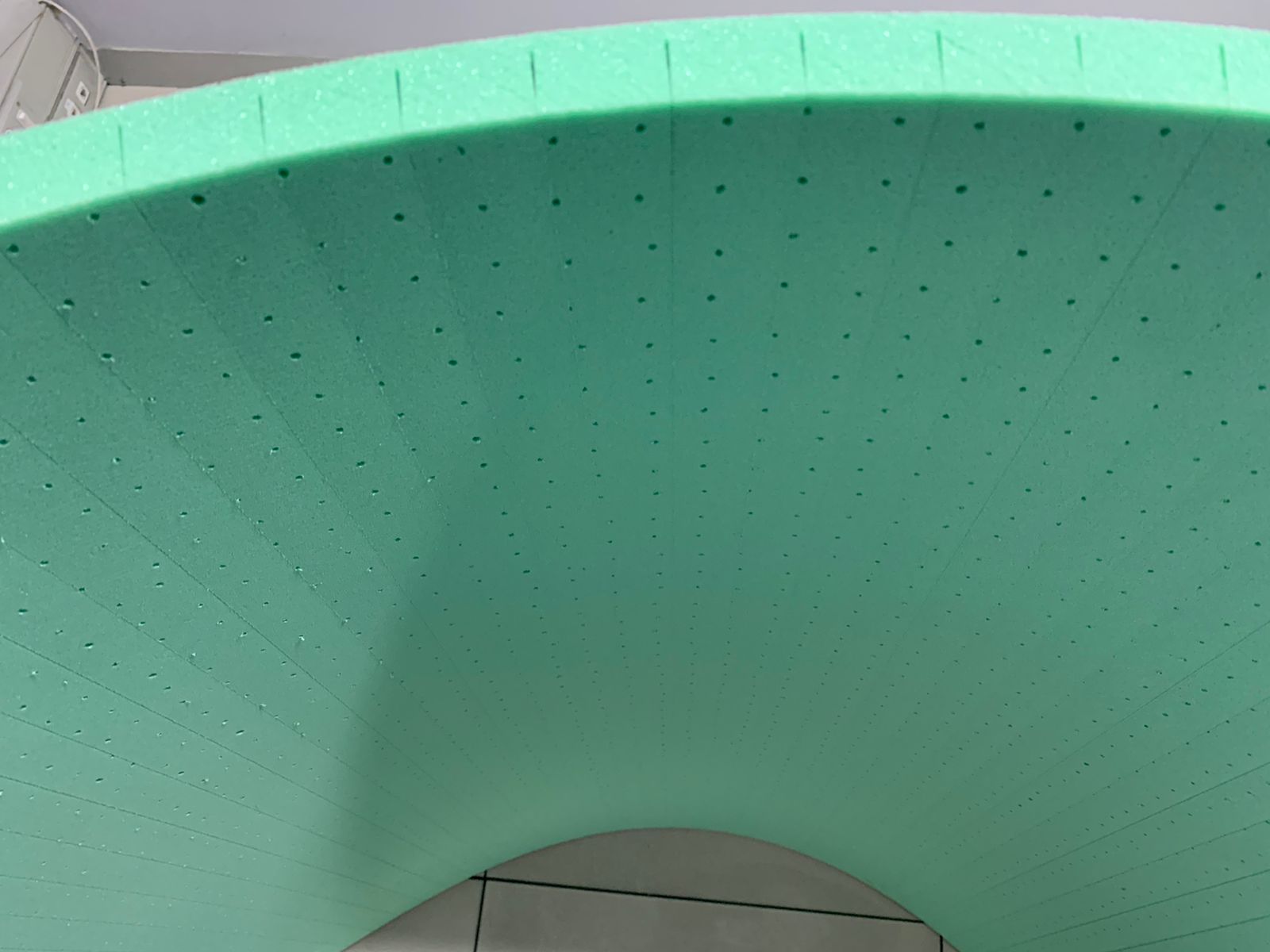

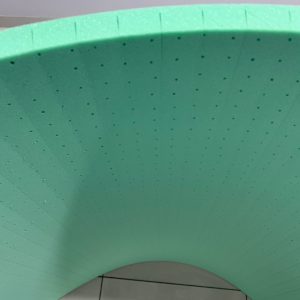

Aerontec has developed the only structural foam core processing plant in Africa, which has reduced foam supply lead times for our advanced composites customers from months to days. Extensive warehousing and state of the art equipment allow PVC and PET foam blocks to be sliced to the thickness and drilled for air release or resin flow. The latest capability is the in-house designed Multi-Cut Contour Core, or MC3 equipment, which provides a tailored, the flexible core that can bend to follow the contours of boat hulls or similar curved structures. Apart from providing a contourable core, the MC3 capability can also be used to provide resin flow paths for vacuum infusion processing. The equipment design allows the cuts to be tailored to achieve the desired curvature with the lowest resin consumption. Multiple cuts also allow for resin infusion without drilling the foam sheets, as the cut intersections allow the resin to flow through the core.