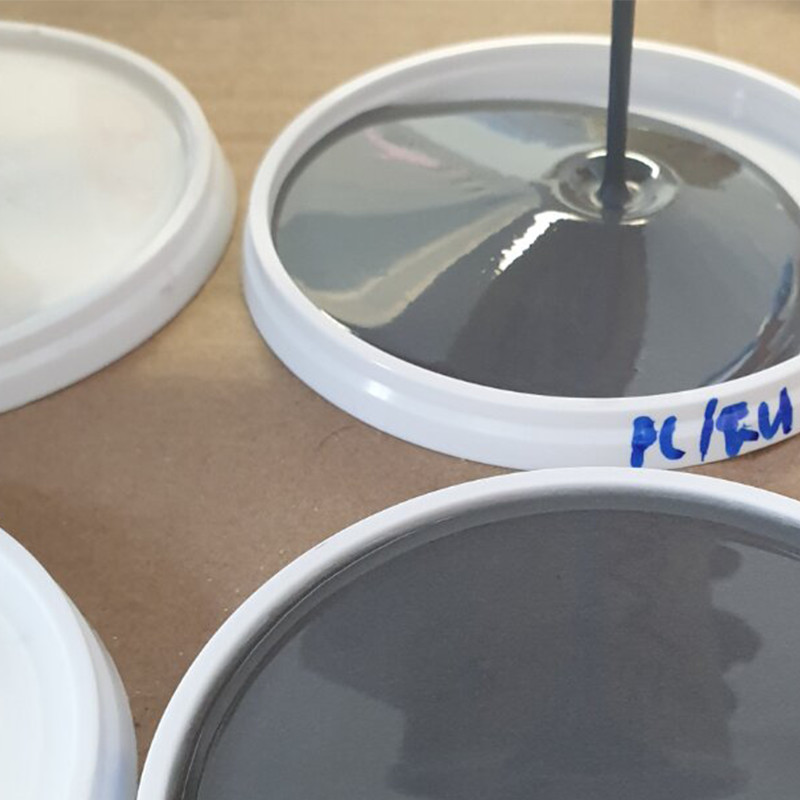

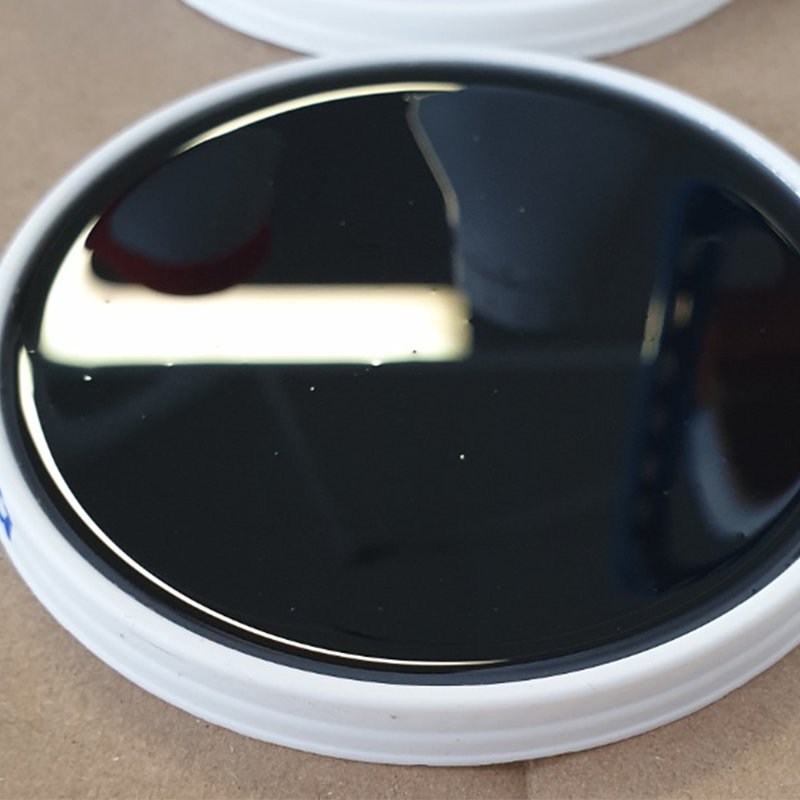

PC26 + G226 Fast Cast

Two-component odourless system. The filler can be added in the suggested ratio or in a different ratio depending on the application and on the required thickness. Very high quality of reproduction. Low exothermic peak. Low shrinkage. The use of Martinal filler (mix ratio 100:100:150) allows production of components with lower specific weight.