Hey there,

Time flies – we’re already halfway through 2023!

In this email, we’ve got some updates about our Silicone Vacuum Bags and our PVC Structural Foam processing plant, and lastly, some news about Sicomin’s hardeners.

Let’s get into this month’s newsletter.

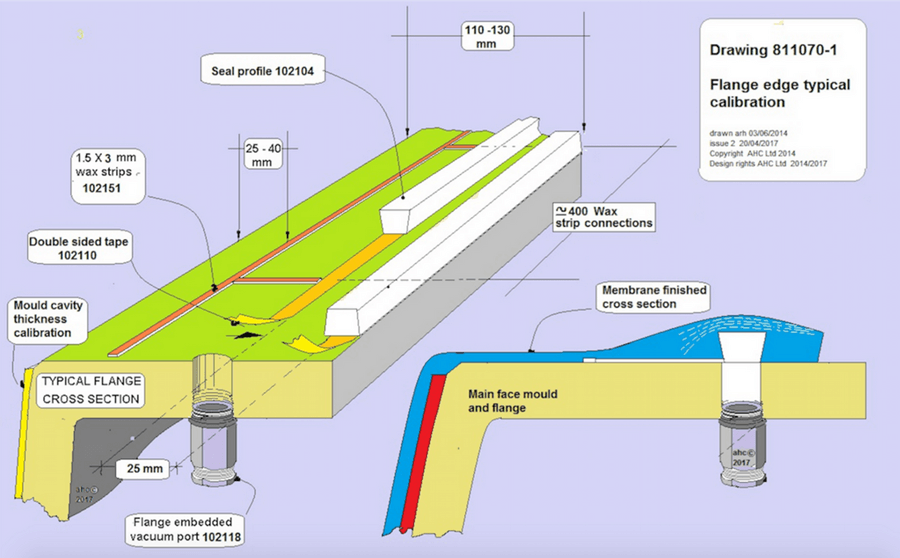

Silicone Vacuum Bags: fiRST® Technology

It’s been an impressive journey for one of our infusion customers, one having surpassed the production of 200 parts in just three months. Our fiRST® Silicone Membrane is not just keeping up; it still looks as good as new. Here’s a quick snapshot of what sets our fiRST® Silicone Vacuum Bags apart:

- Consistency in Production: Consistent repeatably infused part weight, generally deviating no more than ½% each time.

- Reusable & Efficient: Can be used up to 500 times, with consistent production weight.

- Cost-Effective: Our silicone vacuum bags become a more economical choice compared to consumable alternatives after approximately 30 cycles.

- Speedy Bagging: Our bags are designed for quick and easy bagging, reducing labour-intensive setup times.

- Ideal for Infusion and Debulking Prepreg: Our vacuum bags are free from silicone contamination, making them safe for aerospace use and perfect for infusion and debulking prepreg processes.

Note: Specific resins like liquid Epoxy and Polyester DCPD blends can affect the reusable life of the membrane. Refer to our detailed document for specifics.

PVC Structural Foam

Our PVC Foam Processing Plant is up and running. Whether you need 1 sheet or 1,000, Aerontec is your go-to destination.

Our promise? Ultra-short lead times and a range of thicknesses, with standard thicknesses always in stock. From drilling to contour cuts, we produce sheets as per your requirements.

SR810 InfuGreen

Sicomin’s SR810 InfuGreen has achieved DNV-GL certification with the SD477x range of hardeners. This accomplishment means that the bio-based GreenPoxy 33 laminating system and the SR810 InfuGreen infusion system will now share the same range of hardeners. This development simplifies logistics, allowing us to stock only one range of hardeners, which can be blended for intermediate gel times when needed.

Why choose SR810 InfuGreen?

- Certified Excellence: Global standard assurance with DNV-GL.

- Flexibility: Blendable for tailored gel times.

- Eco-Conscious: Bio-based components ensure sustainability.

- Innovation at its Best: Marrying environmental responsibility with quality.

Read more about Sicomin’s SR810 InfuGreen on our website.

And that’s a wrap on our July newsletter.

If you have any questions, you can email us at info@aerontec.co.za or give us a call.